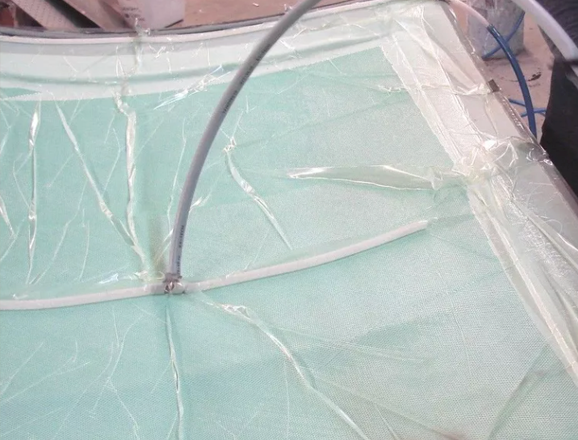

Resin Infusion:

The Future of Pop Top Roof Manufacturing

During 2024, we are moving from hand layup moulding to resin vacuum infusion moulding. To understand 'our why,' think stronger, lighter, stiffer, and better for the environment.

The Benefits of Resin Vacuum Infusion Moulding

1. Superior Strength and Durability Resin infusion creates composite parts with a higher fiber-to-resin ratio compared to traditional hand layup methods. This results in components that are stronger and more durable, ensuring that your pop top roof can withstand the rigors of the road and harsh weather conditions.

2. Lighter Weight By optimizing the amount of resin used, vacuum infusion produces lighter parts without compromising strength. A lighter roof enhances your vehicle’s performance, fuel efficiency, and overall handling, making your travel experience more enjoyable.

3. Enhanced Stiffness Vacuum infusion ensures consistent resin distribution and better fiber alignment, leading to stiffer and more rigid structures. This rigidity translates to better stability and reduced flexing or deformation over time, maintaining the structural integrity of your campervan roof.

4. Environmental Benefits The closed mould process of resin infusion significantly reduces volatile organic compound (VOC) emissions compared to the open mould hand layup method. This makes the manufacturing process more environmentally friendly, aligning with our commitment to sustainability.

5. Improved Quality Control The vacuum infusion process allows for greater control over the resin content and distribution, resulting in fewer defects and higher quality parts. Each pop top roof produced through this method will meet stringent quality standards, ensuring you receive the best product possible.

Conclusion Our transition to resin vacuum infusion moulding marks a significant improvement in the quality and performance of our pop top roofs. This advanced manufacturing technique offers numerous benefits, making your campervan roof stronger, lighter, stiffer, and more environmentally friendly. Stay tuned for more updates as we implement this exciting new process.

By adopting resin vacuum infusion moulding, we are not just enhancing our products; we are also contributing to a more sustainable future. For more information and to see our latest offerings, visit our website.